Most assays conducted across the globe, from those used in genomic or proteomic research to those critical in food testing, come in the form of ready-developed assay kits. The industry is highly profitable —the assay kit market for omics research is currently over $1B and is growing at 5% CAGR. With so much promise and opportunity, many innovators are looking to quickly bring their assay kits to the market to help laboratories get the answers they need.

In trying to maximize product success and maintain their reputation in this market, assay manufacturers face many challenges, from minimizing the chance of variability in results to assuring accuracy. One of the most prominent challenges is catering to the growing need for scaled throughput applications. While manual kits can be optimized to simplify and standardize workflows and alleviate some of this burden, it isn’t the only option.

Automating your kits with a dedicated automated liquid handling platform offers a powerful and attractive solution to all these challenges. What’s more, tailored automation solutions can be integrated into your assay even if you have neither in-house capability to develop a platform nor the desire to support the instrumentation post-sale.

In this article, we discuss how using an automation platform can help you overcome critical challenges in creating optimized high-throughput assay workflows. We also explore options for incorporating them into your assay kits to minimize burden and maximize time-to-market.

Scaling and Optimizing Liquid Handling

The value of automating the liquid handling aspect of your assay encompasses three key areas:

• Greater scalability. Automating manual liquid

handling steps makes pipetting more efficient and reduces the chance of error (and thus

the need for reruns). This opens capacity for significantly scaled throughput using your

kit without the risk of the reduced quality of results seen when accelerating a workflow

that uses a manual assay.

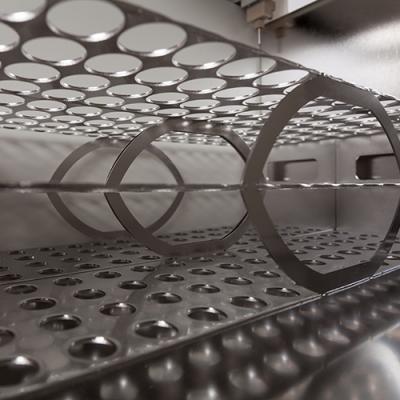

• Assured reproducibility. Manual assays can be impacted by user-to-user variability, regardless of how experienced the pipettor. Automated liquid handling platforms operate a finely tuned action, reliably and repeatedly. This means you can be confident that your customers get the same output no matter who is involved in the workflow.

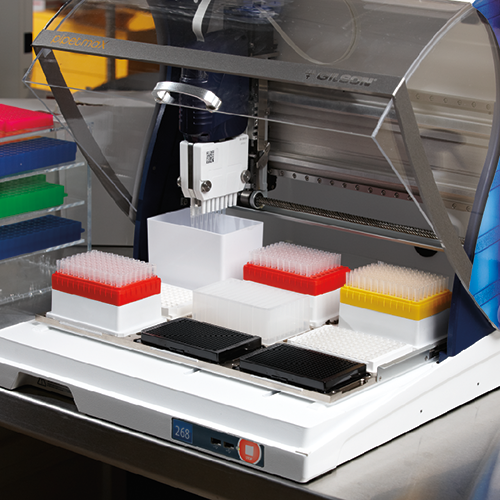

• Greater method control. Assay manufacturers that incorporate automated liquid handling platforms into their solutions can sign off on the exact, optimal method that runs their kit on automated platforms such as Gilson’s PIPETMAX®. As a result, assay manufacturers can enforce the flawless operation of their kits, ensuring their customers get the best results.

Finding an Automated Solution

The benefits of automated liquid handling are clear. What may not be clear is the best approach to developing a tailored automation solution that can accompany your assay kit.

Building Your Own Automation Solution — A Path Fraught with Challenges

One of the options open to assay kit manufacturers looking to leverage an automated liquid handler is building a solution in-house. Such an undertaking, however, can be difficult. First, developing your own automated platform requires extensive expertise spanning R&D, engineering, manufacturing, quality control (QC), and official certification, not to mention the burden of after-sales support. Many smaller companies simply don’t have such resources, and if they do, they are often already tied-up with other business-critical operations.

Second, the typical time span for creating an automation solution is several months to years, which becomes significantly longer if the necessary expertise and resources are not already in place and ready to go. This approach is wholly unsuitable for those looking to corner a new market opportunity quickly.

Even after a solution has been developed and manufactured, several key challenges remain, complicating the path to product launch success. For example, the newly created product will still need to undergo significant in-field testing and safety certification, depending on the geographical territory to be covered, if the manufacturer wishes to release a product that can reliably deliver for end-users without risking damage to the manufacturer’s reputation. This requires another set of skills and further internal resource allocation.

Part of ensuring product quality and consistent functionality also extends beyond the time of sale —manufacturers must be able to deliver ongoing, timely expert technical and maintenance support on a global scale. Indeed, having deep technical expertise on hand post-purchase is a critical consideration for those purchasing automated solutions and equipment. Delivering such support is costly and beyond the ability of many assay kit manufacturers.

By fully outsourcing the development and manufacture of your tailored liquid handling solution, the hurdles and costs of in-house development and manufacturing are simplified or sidestepped entirely. Ultimately, this means delivering a precise, reliable product to market in the fastest possible time.

OEM Collaborations — A Smoother Route to Success

Considering these challenges, those seeking an automated liquid handling solution for their assay are increasingly turning to a different approach that leverages ready-built infrastructure, deep expertise, and vast, rapidly deployable technical support networks — partnerships with original equipment manufacturers (OEMs).

Broadly speaking, OEMs produce equipment and components that are used in (or as) the products of another company. In the case of liquid handling solutions, it means an organization with the expertise, skills, and ability to develop a custom liquid handling platform that’s right for the idiosyncrasies of a specific assay. By fully outsourcing the development and manufacture of your tailored liquid handling solution, the hurdles and costs of in-house development and manufacturing are simplified or sidestepped entirely. Ultimately, this means delivering a precise, reliable product to market in the fastest possible time.

An OEM Partnership with Gilson: Reliability, Flexibility, Precision

While the benefits of using OEMs are clear, not all OEMs are equal. OEM partnerships are often long-term, and choosing the wrong partner can end up costing more than it saves. Selecting the right OEM, therefore, requires a careful evaluation of the capabilities, expertise, and extended support on offer.

With more than 40 years of experience in OEM partnerships, Gilson is well equipped to provide reliable and precise liquid handling components, products, or complete systems tailored to your assay. Our depth of know-how is matched only by the dedication of our technical experts, who are on hand to guide you through the entire journey.

So, what makes Gilson an ideal OEM partner to automate your liquid handling workflows and give you the first-to-market edge over the competition?

Decades of Proven Liquid Handling Platform Expertise

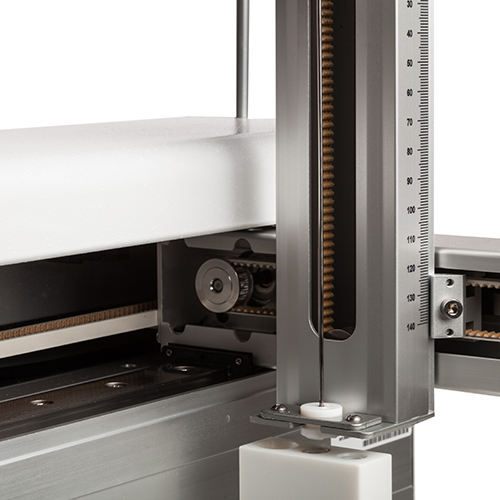

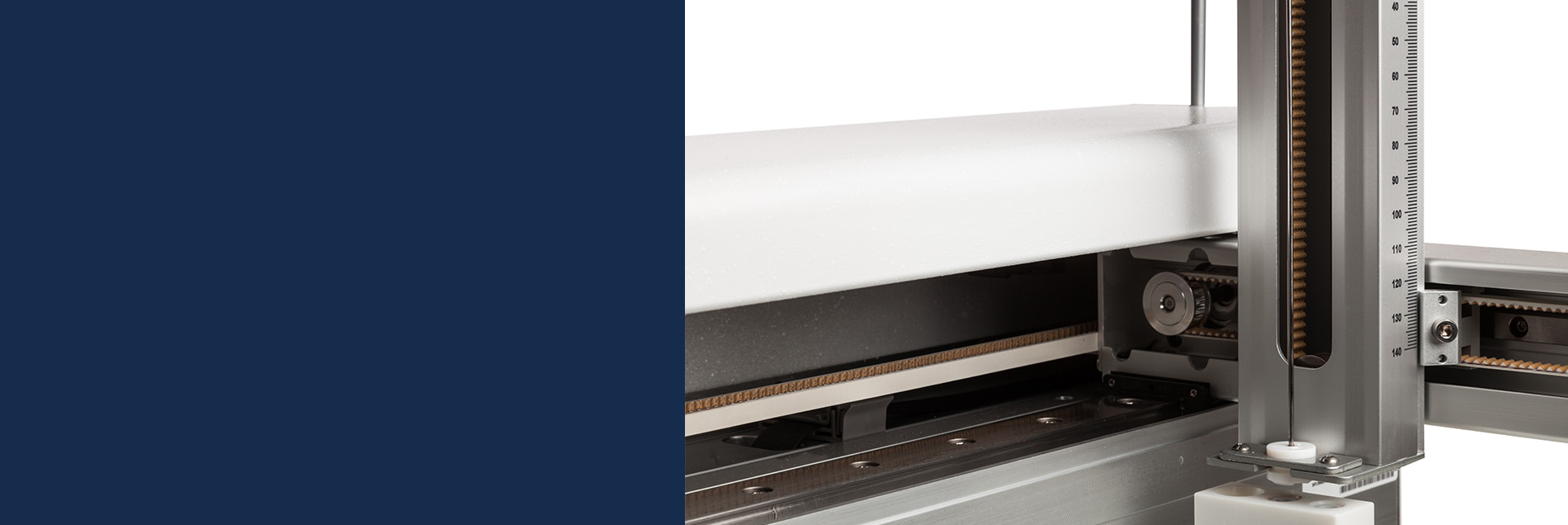

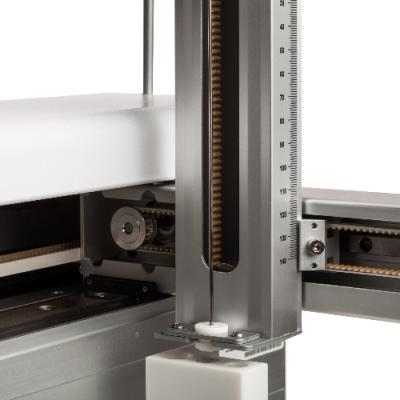

Five decades of experience in liquid handling solutions means we can deliver highly customized, reliable solutions across various applications that have stood the test of time. Our ability to build a quality platform enables you to provide the customer experience that complements your product perfectly and reflects well on your brand. Customization can be applied to our full range of platforms, whether you want tailored hardware, optimized software, or both. The result is a turnkey solution that’s ready-optimized for your assay, right from the moment of unboxing.

As a Gilson partner, you can also be sure that whatever liquid handling system you choose, you’ll get a team of research and development scientists and engineers to guide and support the development of your ideal solution from the start.

Impartial and Kit-Agnostic Solutions for Better-Fit Customization

Many OEMs develop and sell assay kits alongside their automated liquid handlers. As such, their automation platforms are typically tailored to get the best performance out of their own kits, limiting their ability for broader and deeper customization.

Unlike these OEMs, however, Gilson does not produce or sell assay kits. We only sell hardware. That means we can partner with you in a truly kit-agnostic and impartial way, so you get a solution whose only aim is true integration with your kit, and optimized performance as a result.

A Bespoke Relationship That Seeks Your Success

With Gilson, OEM customers also get access to a range of business models tailored to their individual requirements.

For example, we can sell hardware directly to you for sale to customers, providing you with an additional revenue stream and a high-quality instrument that’s branded as your own. Alternatively, we can sell hardware directly to the customer, partnering with you to optimize the hardware configuration and taking care of all customer and technical support.

Custom Protocols for Motorized Pipettes

Did you know that you can sell custom motorized pipettors, too? Our solutions can aspirate specific volumes at defined rates to meet the needs of your kit. In addition, the pipettor can pick up a second reagent as part of the process to then dispense at a specified volume, saving your customers effort and time.

Capitalize on Opportunities and Get to Market Faster, All with Gilson as Your OEM Partner

Today’s market poses fierce challenges for assay kit manufacturers. But with most assay kits being manual and the need for high-throughput capabilities growing, there are also rich opportunities to capture new market share.

Injecting scalability into your assay workflows with an automated liquid handler is a powerful way to pursue such opportunities. With the right OEM partnership, developing and getting an automated platform to market can be fast and cost-effective.

By partnering with Gilson as an OEM, you’ll get access to the expert insights of a stable, well-established team that works with you to meet your needs. Customization can flow unhindered by assay kit partiality. Additionally, a rich network of global experts will be on-hand to smooth the path to market, whether you’re a small start-up with little experience or a large market leader with an established reputation to protect.

Contact us today to find out how we can support your liquid hanlder development project through a truly collaborative OEM partnership.