For many labs across the globe, speeding-up assays and increasing experimental throughput are essential for maintaining a productive workflow amid ever-growing demands.

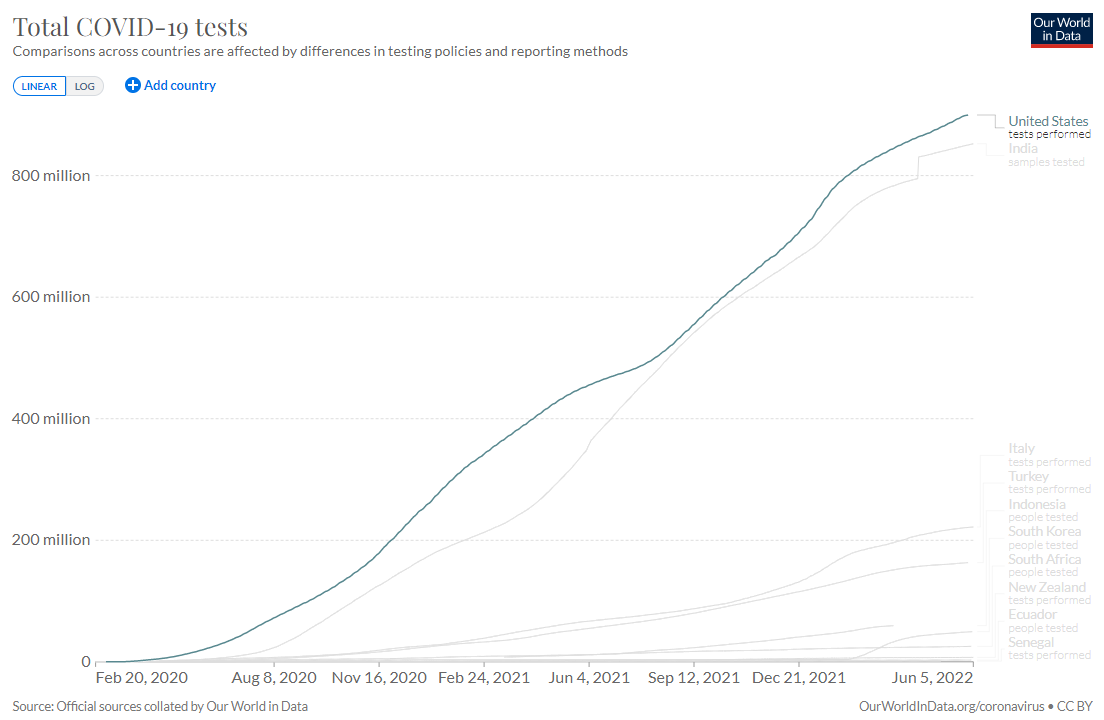

The COVID-19 pandemic is a prime example of labs needing to increase their throughput, as the US alone has carried out more than 700 million SARS-CoV-2 tests since 2020.

Globally, qPCR remains the gold standard for SARS-CoV-2 diagnostics. Positive samples may also require next generation sequencing (NGS) to understand the progression of the virus and its mutations. Automated liquid handling workflows play an essential role in helping scientists battle the spread of the virus to get ahead of any future variants. Many laboratories have adopted automated liquid handling systems to reflect this need for fast, reproducible, and high-throughput sampling.

Figure 1: Our World in Data chart showing the total number of COVID-19 tests from February 2020 to June 2022. Source

Here, we look at how automated liquid handling systems assist labs by improving workflows, increasing reproducibility, and maximizing the throughput to handle the necessary testing demand. We also explore some of the liquid handling robots available for labs that want to automate their workflow.

Key Takeaways:

- As labs face increasing sample throughput and pressure on staff to turn around results quickly and accurately, there are a variety of automated liquid handling systems and platforms available that allow for unattended pipetting and associated workflow steps

- Automated liquid handling systems allow labs to scale up their sampling and analysis protocols

- Our automated liquid handlers provide you with a range of features and capabilities that ensure consistent and reproducible results

What are Automated Liquid Handling Systems?

Robotic or automated liquid handling systems perform repetitive pipetting tasks and sample preparation or microplate washing protocols. Laboratories use these systems to reproducibly process large quantities of samples through the various stages of their protocols.

Typically, automated liquid handling systems are great for:

- Precise control of repetitive aspiration and dispensing tasks

- Unattended operation, allowing technicians to invest their time in more value-adding tasks

- Increased throughput through overnight operation

Systems may also come with a set of pre-programmed protocols that help laboratories get started with sampling and analysis quickly. While the type required will depend on the exact application, these systems provide a versatile platform that can support almost any liquid handling requirement.

Why Laboratories Use Automated Liquid Handling Systems

With proper training, manual pipetting can be done accurately by a technician and provide precise results. Although human error can be introduced, humans remain the best multi-axis system with excellent fault sensing and management capabilities. Where humans do need help, however, is when technicians need to carry out thousands of repetitive tasks, which can lead to fatigue and repetitive strain injuries — in addition to issues with reproducibility.

Automated liquid handling can assist when the protocol calls for a standardized workflow that requires maximizing the sampling throughput. To achieve the required precision while increasing sampling rates, a liquid handler assists laboratories by:

- Consistently positioning and locating the pipette tip for each sample run in bulk and at higher volumes on a large capacity platform

- Automating the sample preparation, including pre-wetting, aspirating, and dispensing the right volumes while controlling the speed of pipetting cycles

- Managing the entire process and recording the sampling data by integrating with downstream equipment

For standardized workflows, automated liquid handling allows labs to free up personnel to focus on analysis and research instead of carrying out repetitive pipetting tasks.

The Main Types of Automated Liquid Handling Systems Available

Liquid handling robots are available in many shapes and sizes. Historically, these systems were expensive, and their size took up valuable lab space. Luckily, modern automated liquid handlers are now more accessible for any lab environment and have a much smaller footprint while providing you with more features. There are liquid handling systems available to meet virtually any need.

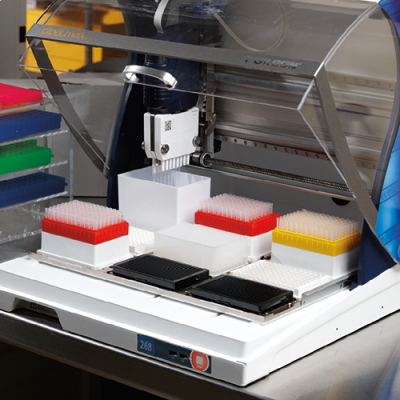

PIPETMAX® Benchtop Liquid Handler

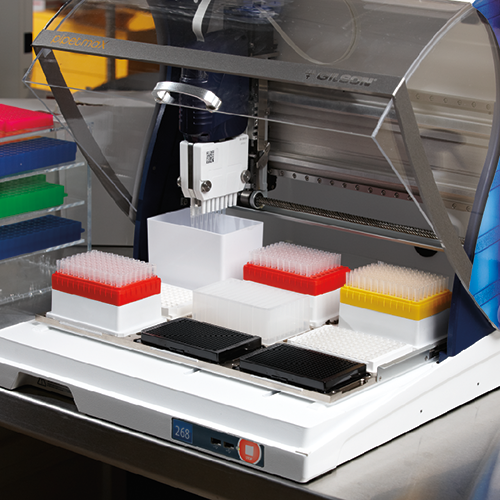

For labs that need a small yet versatile automated pipetting solution, PIPETMAX delivers a wide array of features that enable streamlined workflows. The platform can handle volumes from 1 µL to 1200 μL.

You can control your protocols using the TRILUTION® micro V3.0 software, which features a smart and intuitive interface. Tip pack configurations and running protocols are massively simplified, freeing-up lab personnel time and driving productivity.

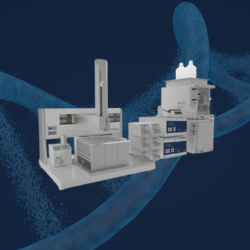

GX-281 Liquid Handler and Autosampler

When you need a larger capacity system that provides you with automated, unattended liquid handling capabilities, consider the GX-281 Liquid Handler and autosampler. You can configure the system for injection, fraction collection, and, if necessary, re-injection. The syringeless solvent delivery system gives you variable flow rates, making it a revolutionary automated liquid handling platform.

Labs can benefit from the dynamic working range of between 2 μL and 100 mL, and process samples at a flow rate of up to 25 mL/min. This versatile platform can also handle up to five reservoir solvents and six rinsing solvents.

GX-241 Liquid Handler

The GX-241 Liquid Handler is another flexible and reliable platform that comes with a small footprint. With only 39 cm (or 16 inches) of linear bench space required, the GX-241 is suitable for small or large volume injection ranging between 1 μL and 5 mL with a minimal dead volume using a direct injection design.

You get two transfer ports for moving samples to off-bed detection devices, and it can hold up to four shallow or deep, 96-well microplates. If your lab needs a liquid handling station that gives you maximum flexibility, the GX-241 offers you everything you need to increase throughput and run unattended protocols consistently.

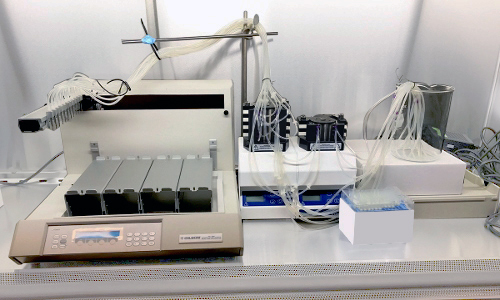

Gilson Tube Filling System

If you’re looking for a solution to automate large-scale vessel filling, look no further than Gilson’s customizable Tube Filling Systems. These systems can fill bottles, tubes, vials, and microplates, so you’re prepared for any protocol. With no external computer or software required, the system is easy to use and can fit easily in biosafety cabinets — perfect for a smaller lab.

The Tube Filling System gives better accuracy in measurements and increases lab productivity, plus saves time. It additionally benefits from adjustable dispense head spacing and peristaltic pumping technology, giving your laboratory the flexibility it needs in workflows.

Figure 2: An Example of a Gilson Tube Filling System Setup

Discuss Your Liquid Handling System Needs with Gilson

With so many different options available, an automated liquid handling solution can meet the needs of almost any lab. Gilson is committed to providing solutions that connect your entire lab for increased reproducibility, throughput, and data quality. We develop a range of automated liquid handling solutions that support the world’s labs at scale and according to their exact requirements.

To find out more about our automated liquid handling systems, get in touch with Gilson today.