In the ever-evolving lab landscape, the movement from manual liquid handling to automation marks a transformative step forward in your workflows. Switching to an automated process not only enables significantly more effective use of personnel time, but also removes operator error for reproducible results and increases the accuracy and precision of assays.

However, the transition to an automated process is not always straightforward. Most importantly, automated instruments require precise instructions to perform the task correctly. What’s more, unlike humans, automated liquid handlers do not respond to visual or intuitive cues.

Further complicating the transition to automated liquid handling is the fact that not all systems are created equal. For example, the hardware varies significantly from instrument to instrument, with differing levels of user-friendliness. Additionally, liquid parameters must be meticulously optimized, and unfortunately, not all instruments possess the same capability to accommodate this need.

At Gilson, our instruments — PIPETMAX® and the GX range of Liquid Handlers — are designed to primarily focus on ease of automation and scalability. In this article, we delve into the challenges that can arise during this transition and explain how Gilson's solutions and services can ease the process of transferring your manual methods to an automated system.

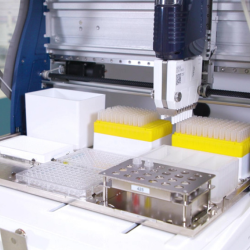

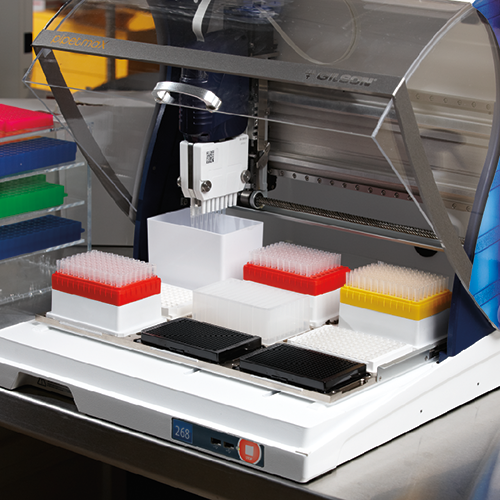

PIPETMAX Automated Pipetting System

Gilson’s PIPETMAX is the automated pipetting solution you need for consistent, accurate, reproducible, and versatile liquid handling. PIPETMAX is:

- Compact: Save valuable space, as the benchtop size easily fits into any lab

- Trustworthy: Enjoy reliable and consistent pipetting from well-established PIPETMAN® technology

- Autonomous: Spend more time innovating while PIPETMAX reduces tedious sample prep work

PIPETMAX shines in numerous applications, including:

- Automated biochemical and cell-based assays

- Automated NGS library preparation

- Automated RNA normalization and plate setup

- Automated RT-qPCR Assays from virtually any supplier

Learn More

Gilson: Flexible Hardware to Handle Almost Any Workflow

The hardware of your automated liquid handling instrument plays a crucial role in the overall effectiveness and adaptability of your automated procedures. As different instruments have their own strengths and capabilities, your selection can significantly impact the smoothness of your transition from manual to automated workflows.

Three key considerations underscore a solution’s capability to facilitate the transfer of your manual processes to an automated solution — the tips, the volume range, and the labware used, all of which we explore in more detail below.

Tips

In manual workflows, tip selection remains critical to ensuring maximum accuracy and precision. As you transition to an automated system, the same principle holds. To ensure the highest level of sample integrity, the smallest tip for the volume should always be chosen. Gilson tips are designed for ultimate flexibility, and come in a variety of sizes.

Figure 1. Gilson pipette tips come in three sizes to accommodate virtually any workflow.

PIPETMAX aspirates and dispenses through a disposable tip, which can either be exchanged to prevent contamination or reused for reagent dispensing. The tips used are standard Gilson tips — the same as those for manual pipettes. Our tips are:

- Constructed of high-quality propylene, for product reliability

- Available in various formats, including sterile and with filters, for flexibility in your workflows

- Manufactured in a clean environment, reinforcing our commitment to accuracy

Our GX Liquid Handling systems use washable probes. This design provides an economical alternative to disposable tips, yet helps you avoid cross-contamination with active wash stations to ensure the integrity of your samples.

Whether a PIPETMAX or a GX Liquid Handler is more suited to your needs, you can be sure your automated system prevents sample contamination, even in biological assays.

Volume Range

Laboratory workflows are as diverse as the fields they serve, often requiring the handling of a wide array of volumes. In manual operations, personnel are accustomed to switching between different size pipettes to accommodate varying workflows.

Gilson’s wide volume range capability is one of the standout benefits of our systems. Our instruments provide labs with the ultimate flexibility, allowing a single instrument to adapt to a vast array of workflows. PIPETMAX, for example, is capable of handling volumes from as small as 1 µL up to 1200 µL, while the GX range of Liquid Handlers have different volume ranges from 10 µL to 50 mL and higher.

Labware

Labware flexibility is inherently simple with manual methods and is critical to retain when transitioning to automated systems. Gilson’s automated solutions ensure the continuity of your operations and ease of transition, as they are compatible with a wide variety of labware — from flip cap tubes to standard SBS footprint racks.

However, there are certain labware considerations when moving to automated workflows. For optimal functionality, our systems require specific racks, which are readily available from Gilson. Our PIPETMAX system also utilizes reservoirs instead of bottles of reagents, allowing for the use of multiple tips and greater efficiency.

Gilson’s automated Liquid Handling systems are highly adaptable. Both PIPETMAX and our GX range of Liquid Handlers grow and evolve with your lab needs — from initial research stages through to scale-up — to provide a solution that’s as dynamic as your workflow.

When transitioning to automation, you may still require the use of a hood for safety purposes. Both our PIPETMAX and GX Liquid Handling systems have small footprints, meaning they occupy less space and can be easily moved to and from fume hoods as needed. Such an innovative design not only ensures personnel safety but also helps optimize the available workspace.

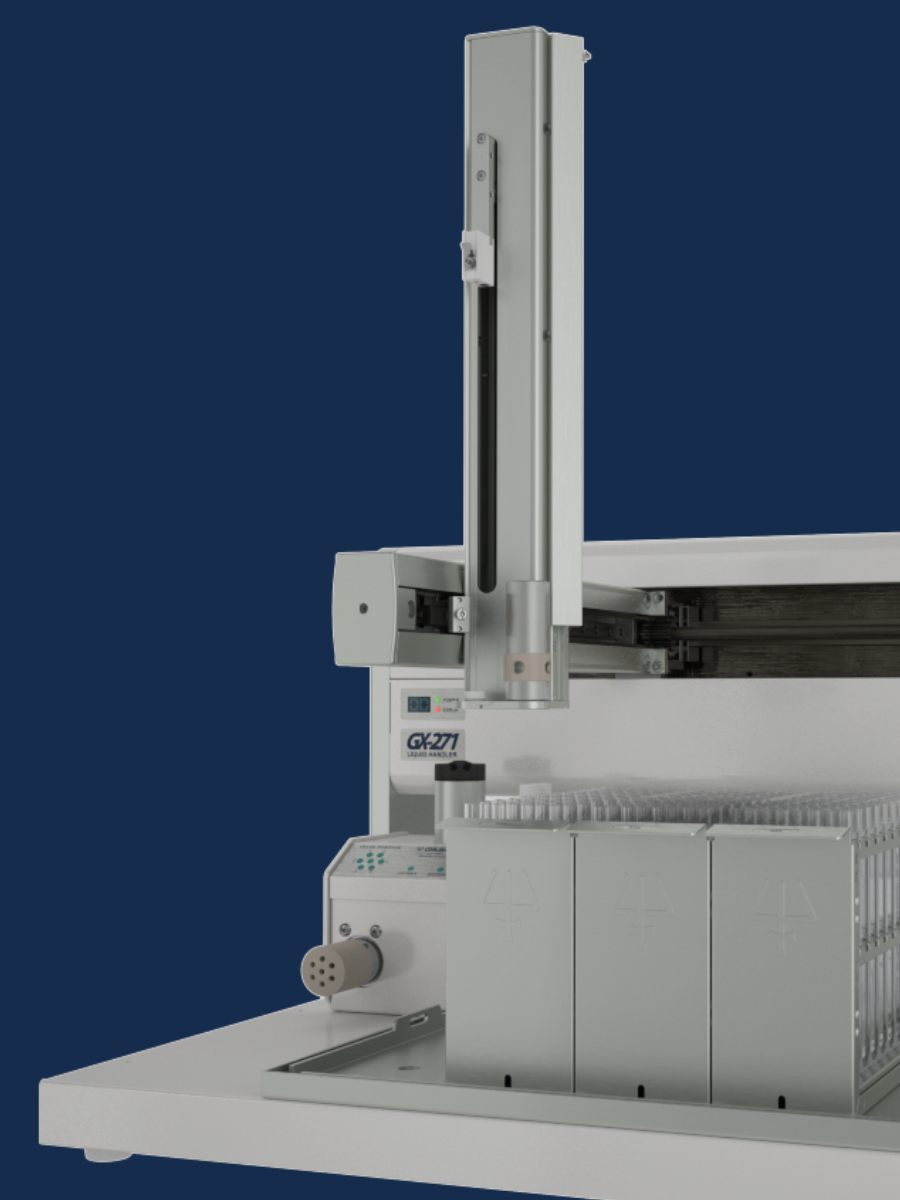

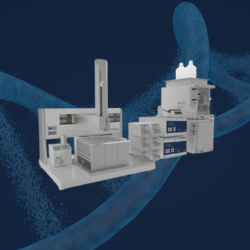

GX Liquid Handlers

Gilson’s automated GX range of Liquid Handlers deliver the precise control you need for reproducible lab results — all with less effort. As well as being reliable, all our GX Liquid Handlers are space-saving, as they perfectly balance size, performance, and capacity.

Not sure which automated liquid handler is right for you?

- The GX-241 Liquid Handler: a two-rack platform makes it ideal for labs with limited bench space and lower throughput

- The GX-271 Liquid Handler: a small footprint, medium-capacity instrument for greater throughput

- The GX-274 Liquid Handler: four probe capability for faster workload completion

- The GX-281 Liquid Handler: a versatile large-capacity platform for labs that require high throughput

Learn More

How to Begin Your Manual to Automated Method Transfer

Understanding the transition from manual to automated liquid handling begins with appreciating what automated systems can and cannot replicate from your manual workflows. In essence, automated liquid handling may not mirror exactly what you do by hand. For instance, your current workflow might involve opening reagents, dealing with various types of sample tubes, or even using an ice bucket — steps that automated systems can’t replicate.

Instead, the focus of automated liquid handling is to get you from point A to point B accurately and reproducibly. Automated instruments can perform most tasks a human can but need to be instructed accurately how to do so. This can be a challenge as humans instinctively respond to visual cues — such as real-time responses based on liquid viscosity — whereas an automated system relies purely on the instructions given. Ultimately, if the instructions are incorrect, the instrument will not execute the task as expected.

Liquid handling instructions are conveyed to the instrument via a programmed method, with each workflow requiring a different one. Methods can be written in various ways to achieve different objectives, such as maximizing accuracy versus speed, or changing tips frequently versus conserving tip usage.

For a successful automated liquid handling operation, every method needs to meet four fundamental criteria by specifying:

- Where the liquid is coming from

- Where the liquid is moving to

- How much liquid is being transferred

- How to perform the transfer, i.e., the liquid parameters

We explore these liquid parameters in more detail in the following section.

Automated Liquid Handling Parameters to Optimize

Liquids come in a variety of different forms — including aqueous, volatile, viscous, or frothy. As such, your automated liquid handler needs to have a set of conditions that are specific for each type of sample or reagent. For optimal liquid handling using your automated instrument, both PIPETMAX and our GX range of Liquid Handlers can optimize many different parameters. Here are nine of the most important:

- Aspirate/dispense pump speed (flow rate)

To improve experiment throughput, your method should be as fast as possible. However, if you handle your liquid too rapidly, you risk bubbling, which leads to inaccurate measurements.

With Gilson’s Liquid Handling solutions, aspirate and dispense speeds are fully programmable in the software. You can be confident that your method is performed the same way time and time again, regardless of user.

- Aspirate/dispense equilibration time

The time the tip is left in the sample, after aspiration or dispense, affects liquid handling, and the most appropriate time is determined visually when performing the step manually. Longer equilibration time is particularly vital for viscous samples — if the tip isn’t left in long enough, then the sample won’t settle. Too long, however, and the method is drawn out.

Gilson’s automated liquid handler software, TRILUTION® LH, can incorporate equilibration time into a method once it has been defined. By factoring in this aspect, you can ensure accurate pipetting and correct volume measurements every time.

- Purge

To dispense the sample from the tip, an amount of air can be aspirated before the sample. Sample type must be carefully considered, however, as purging can introduce bubbles into frothy samples.

With Gilson’s Liquid Handling solutions, you can decide whether to purge at each step of the method, depending on the nature of the liquid. Full control in this manner allows you to ensure reproducibility in your automated liquid handling steps.

- Travel air gap

Air can be taken into the tip after the sample, to avoid drips during motion. A travel air gap is useful to protect volatile samples.

A travel air gap can be programmed into your method with TRILUTION LH software. Workflows are reproducible and ensure sample integrity with the ultimate protection of your most vulnerable liquids.

- Submersion depth

Reducing submersion depth leads to a cleaner tip, which is vital to reduce cross-contamination and ensure accurate volumes. A lower submersion depth is particularly important for low volumes and viscous samples. When pipetting manually, personnel will intuitively control how far the tip goes into the liquid to reduce contact.

With Gilson’s automated liquid handling systems, you can program specific submersion depths. Experience accurate volume transfers in your workflows, as you can ensure that minimal liquid coats the outside of the tip.

- Contact versus non-contact dispensing

Both contact and non-contact dispensing are important ways to transfer your liquid, but which method you choose depends on the volume. Contact dispensing is more appropriate for smaller volumes, for example, whereas non-contact dispensing is better for large volumes.

Gilson’s automated liquid handlers offer full control over the dispensation height, meaning that you can choose whether to dispense directly into a liquid or directly onto the surface of a dry plate. Accuracy of your pipetting is improved, regardless of liquid type.

- Side dispensing

Occasionally, the dispensed liquid forms a small droplet that cannot detach from the tip. In such instances, the liquid can undergo side dispensing — that is, the droplet is touched to the side of the vessel for accurate dispensing. Side dispensing is highly beneficial to improve the accuracy of small volume transfers.

You can program side dispensing into any method with Gilson’s automated liquid handlers. By using these systems, even small volumes can be dispensed accurately.

- Pre-wetting

To improve the accuracy and precision of liquid handling, especially for volatile samples, it is important to fully coat the inner surface of the pipette tip. This comes intuitively to those who pipette manually and must be programmable in an automated liquid handling system.

You can program pre-wetting steps using Gilson’s liquid handlers, leading to reproducible and consistent pipetting. The number of pre-wet cycles can also be adjusted to reduce standard error and improve data confidence further.

- Reverse pipetting

Extra volumes of a liquid can be aspirated to improve dispensing accuracy, in a technique called reverse pipetting. After dispensing the required volume, the excess is discarded — either back into the source or into a waste container. Reverse pipetting removes air bubbles from a sample, and is highly useful for difficult liquids such as those that are viscous.

Gilson’s TRILUTION software packages enable you to easily program reverse pipetting into your method. Whether using PIPETMAX or a GX Liquid Handler, you can be confident that your most difficult samples will be accurately dispensed.

Ensure Maximum Efficiency and Accuracy with Automated Liquid Handling

Moving from manual to automated liquid handling is a vital step towards more reliable workflows by enhancing precision and accuracy, reducing error rates, and freeing up invaluable personnel time. However, such a transition requires careful consideration of key factors such as the hardware and liquid parameters. These processes, which are typically informed by visual cues and user knowledge in manual operations, need to be explicitly defined in an automated system.

Both Gilson’s GX range of Liquid Handlers and PIPETMAX are equipped with intuitive features and hardware adaptations to streamline the transition to automated liquid handling, making the process as seamless as possible. By choosing to adopt one of these solutions, you position your laboratory to reap the benefits of consistency, accuracy, and reproducibility in your liquid handling workflows.

You don’t have to take the journey on your own, either, as Gilson has a global support network that can help streamline your transition from a manual liquid handling workflow to automation. When choosing one of our instruments, you will be assisted by our team of highly trained application specialists every step of the way.

Request a quote for PIPETMAX, our GX Liquid Handlers — the GX-241, GX-271, GX-274 or GX-281 — or get in touch today for a demo.