Original equipment manufacturers (OEM) are in high demand as companies turn to them for two main reasons:

Yet, there are many more reasons to team up with OEM partners for laboratory product development. This article will examine the top six reasons and how you can find the right OEM partner.

By choosing to partner with Gilson, you choose from various integrations or complete systems that can easily integrate into your existing product portfolio. This will reduce your development costs and increase revenue.

OEMs are responsible for designing, manufacturing, packaging, and clearing finished laboratory items before being sold to customers. VAPs purchase equipment from OEM companies using their designs and materials branded for the value-added reseller (VAR).

Easy integration and lower development costs are only a few of the reasons to partner with an OEM. Other incentives to partner with an OEM are:

1. Instrument Reliability

You need reliable components so that you can focus on your own customers’ needs. One of the primary reasons to work with an OEM is their extensive experience building specialty components and products. Not only will they produce high-quality products, but parts are also tested to ensure they meet the needs and specifications of the client.

When you partner with Gilson, you can rely on us to provide all manufacturing solutions for any liquid handling equipment to ensure reliability and performance. We provide a warranty to guarantee the quality of the products we develop.

2. Product Line Growth

OEMs will work closely with you to develop your product line. They have a team of experts who can help you with either automated or manual liquid handling products. OEM partnership helps you expand your product portfolio and increase your market recognition. Additionally, our team of engineers can oftentimes recommend customizations to certain product lines to fit customer needs.

In 2021, the global liquid handling system market is worth $3.53 billion. Partnering with an OEM gives you the edge in solving problems and developing new technology to grow your product line and establish your market position.

3. Product Expertise

OEM laboratory equipment is a great option if you are looking for high-quality research devices but don’t have the resources or capital to develop them. They develop devices from start to finish and can usually tailor any instrument required with ease.

OEMs typically have complete control over the products they are manufacturing because they do R&D in-house rather than outsourcing work as other companies do. They’re also oftentimes able to customize each order so that it fits your needs perfectly.

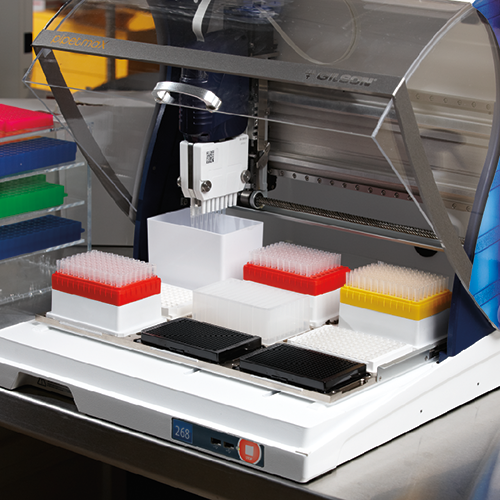

4. Kit Automation

With a value-added partnership (VAP), the OEM retains ownership of installation and support at your customers’ sites. A partnership with the OEM ensures you receive precise liquid handling components and complete systems without needing to outsource them elsewhere.

Customers profit from an improved kit and consumable revenue without investing in hardware maintenance. Kit automation is beneficial to managing better laboratory processes, resulting in more accurate results.

You will work with R&D to validate protocols on a defined liquid handling system for any new or updated products from the OEM. A significant advantage of working with an OEM is lower costs and faster turnaround time when issues arise during commissioning or training sessions.

5. Manufacturer and Equipment Reputation

Engineering teams spend a lot of time carefully developing laboratory devices to use for research. Quality and performance are always the ultimate goals to establish your equipment’s reputation.

OEMs test their devices for quality to guarantee the equipment meets the standards required for laboratory use. They can base this on necessary specifications for the field of research in which the devices are being used.

If you want to make sure your products are the best on the market, then it is imperative that you only choose companies with a good reputation. The OEMs represent what they produce in some way and should provide genuine components for their customers.

6. Customizable Capabilities

Drawing on years of experience in custom liquid handling systems and strong engineering capabilities will help you make your idea a reality. OEMs have the know-how to develop, engineer, manufacture, and maintain all their products so that they work seamlessly with any other equipment or system within your facility.

Here are some reasons to choose a customizable liquid handling system from Gilson:

- Administrative Compliance

- Custom Branding

- Custom Packaging and Literature

- Custom Products

- Distinguished Service and Support

- ISO 9001 Certified

- Modular Design for Easy Integration

- Software Control Options

- Thoroughly Tested and Validated Product

Partner with Gilson to Develop Your Liquid Handling System

Gilson is a leading manufacturer of lab equipment and supplies. We have been at the forefront of scientific instrumentation, from purification solutions to the latest high-throughput extraction technology.

We have been designing and manufacturing laboratory research instruments for over 50 years. We have decades of experience manufacturing modern, efficient, and effective laboratory devices and equipment. Therefore, we are confident you will find what your lab needs with our suite of products and services.

OEM partnership with Gilson will get your idea to market quicker at a lower cost with a trusted partner. Contact us to learn more.